How to Install Glass Mosaic Tile in a Swimming Pool

Background

In European culture, the tradition of decorating pools with glass mosaics can be traced back to early centuries, when skillful craftsmen often installed mosaics throughout pools, from the waterline to the very bottom.

Nowadays, exquisite glass mosaics are making a comeback, used by modern designers to ornament multiple spaces across the home. These beautiful gems are found in elegant backsplashes and eye-catching feature walls, and it is no wonder that they also became top requested for residential pool projects, in particular to create splendid waterlines.

Unfortunately, the demand for installation of waterlines made from glass tile mosaic grows faster than the training of qualified specialists in the field can be carried out. The fact is that glass mosaic is a delicate product, which requires installation methods, different from those used in ceramic or porcelain tile installation.

Both ceramic and porcelain tiles differ from glass mosaic in the thermal expansion coefficients. While ceramic/porcelain products feature a very low coefficient, meaning they don’t tend to expand much when exposed to sun, glass tile mosaic shows a very high coefficient that makes it expand significantly under the solar heat.

Thus, it should be understood that the differences between the materials require careful studying and changes in installation methods in accordance with the stresses to which these materials are usually exposed in today’s exterior pool projects.

Types of Glass Mosaic

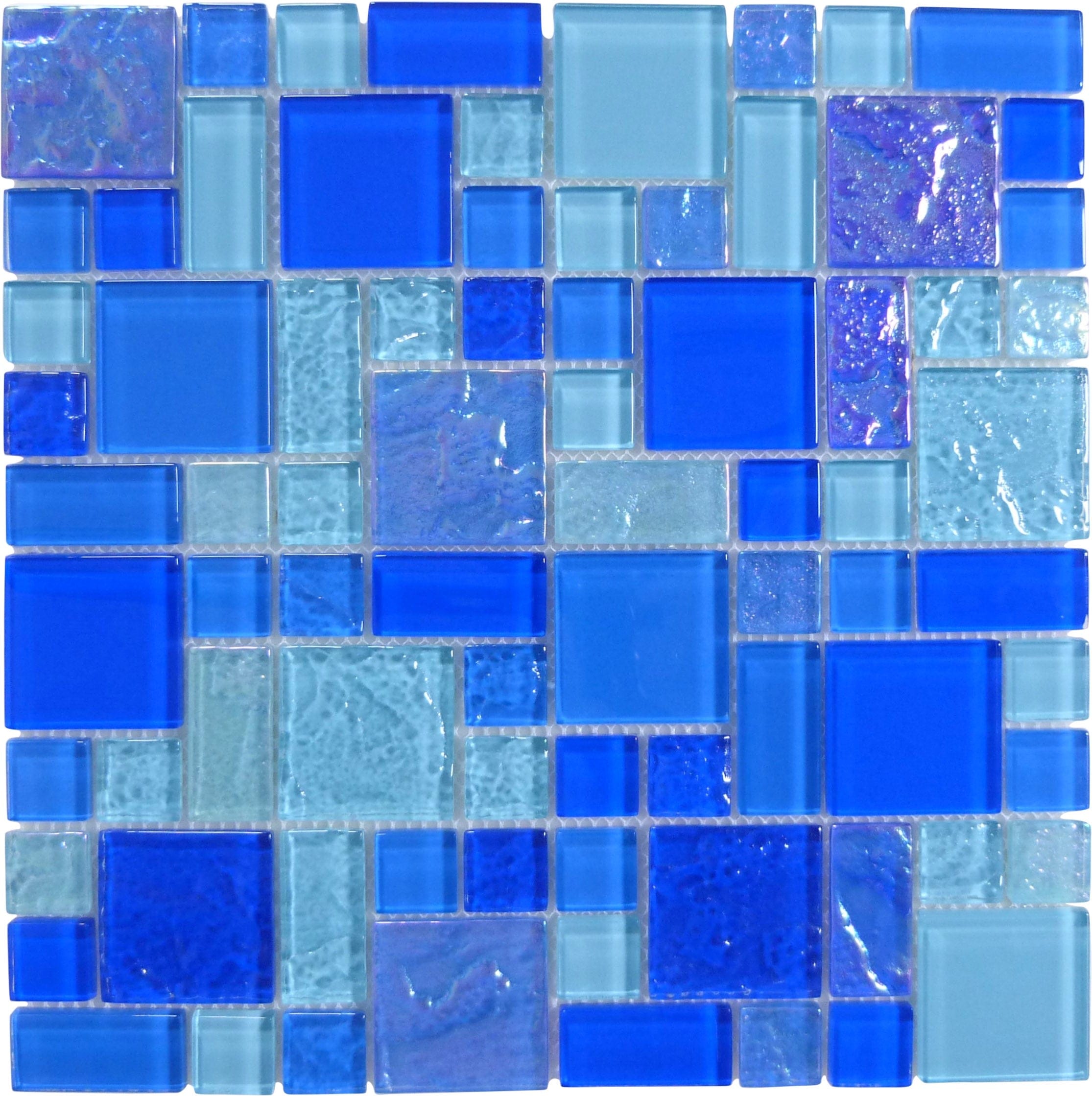

Within modern pool applications, there are 3 types of glass products used in mosaics manufacturing. All of them are characterized by different temperatures at which the formation takes place.

Cast Glass is produced under the temperature of 1600° F, while in the liquid form.

Fused Glass is produced under the temperature of 1023-1599° F by fusing sheets of glass and glazes.

Low Temperature Sheet is produced by coating the back side of glass with colors (with the help of either a heat or cold applied technique) and then heating it at temperatures under 1023° F.

Cast Glass

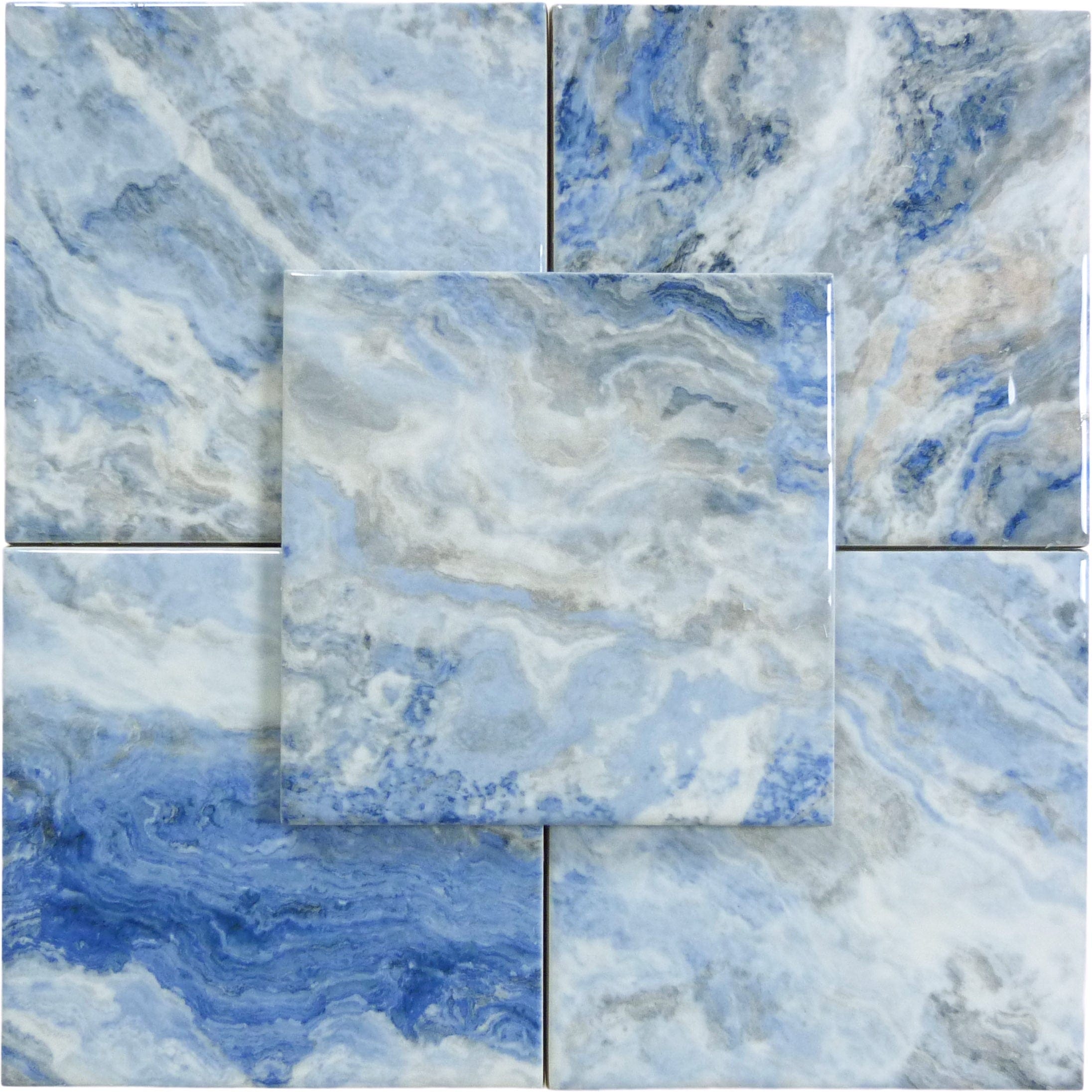

Molds, usually having beveled edges to facilitate the withdrawal of an end product, are filled with the melted glass at a very high temperature. When cooled and hardened, cast glass often shows stained effects and boasts multicolored design.

Fused Glass

The layers of glass sheet and colored glazes are stacked together and gradually heated in a kiln until they fuse and then cooled. This results in acquiring a uniform color throughout the glass and smoothing its edges.

Low Temperature Sheet Glass

Mosaic chips are cut from float glass (like this one used in window glass production) and coated with color on one of its sides by a cold applied or heat applied method. The first one allows achieving beautiful coloration, but cannot be used in pool installations, since it doesn’t provide sufficient moisture-resistance. The second method implies firing to transfer a color applied on the glass bottom, usually supplemented with a white coating behind the color.

Performance Specifications

According to ANSI A137.2 requirements, glass tile must have:

- Tensile Strength (shows what force should be applied to a point load in order to break a tile using a three-point mount) – over 250 pounds for Crystal and over 350 pounds for Cast.

- Thermal Shock Resistance (shows what instantaneous temperature drop a material can withstand) – over 100°F for exterior applications.

- Bond Strength – over 150 PSI for dry applications and 100 PSI foe wet areas.

Mounting (a mounting system used to fix glass tiles) – back or face mounted options. It is important to understand that in back or mesh mounting various adhesives are sometimes prone to re-emulsifying, as well as to creating insufficient coverage. This can result in flaking of glass tiles in wet conditions.

Here are examples of improper glass tile installations:

Installation Manual

Preparation Stage

- Check all your glass tiles for any visible defects like damaged edges and surface, shade differences, etc.

- Watch for lot numbers specified on each box of tile and avoid using tiles from different lots within one installation.

- Check if all surfaces are properly prepared for installation. The temperature has to fall within a 40-95ºF range; they has to be sound, dry and clean with no damages and contaminants that can impair adhesion.

- Make sure that all substrates are plumb and precise, while surface deviation doesn’t go beyond ¼” in 10’.

- If you need to patch, level and prepare the substrate, be sure to choose a proper patching material based on polymer-modified portland cement.

Specific Instructions

If you are going to use glass tile, which has the size of over 1”x1”, it is often recommended by manufacturers to carry out additional surface preparation due to a larger expansion coefficient of such tiles. In that regard, they offer either cementitious or membrane waterproofing. The membrane option also boasts shock-absorbing features, thus covering the difference between an expansion/contraction coefficient of glass and cementitious gunite construction. Besides, by waterproofing you can prevent efflorescence. However, you need to consult your glass mosaic dealer or manufacturer regarding the possibility of using the membrane.

Fluid-applied waterproofing is the most commonly used and usually it is applied without fabric, but you can use it to better understand whether you are applying a sufficient layer of fluid.

The images below illustrate the process of cementitious waterproofing:

Applying Thinset

- Choose a quality latex-modified thinset and make sure it is approved for glass applications and usage in wet or outdoor areas. Also, it has to be compatible with your substrate.

- Put some thinset on the substrate using the flat side of your trowel, while pressing it firmly against the surface and thus performing so called ‘keying in’ mortar.

- Quickly take a notch trowel and put a thicker layer of thinset. It is convenient to use a 3/16x1/4 V-shaped notch or a 1/4x1/4 square notch.

- Avoid putting more mortar than can be covered in 20 minutes, since the mortar will harden.

- After striping with your notch trowel in one direction, use its flat side to level the surface out. You need to get a smooth uniform 1/8 inch bed of the thinset prior to laying your mosaic.

If you fail to smooth the notches, you can get the effect as it is shown below, since glass tends to magnify those gaps created by the notched mortar, while the grouting only worsens the situation by trapping the air inside.

- To better smooth the notches, also put a thin layer of mortar on the back of your glass tile, using the flat side of the trowel. This is especially recommended for glass tile featuring a completely transparent texture, since by spreading thinset on its back you will fully hide the notches of substrate. Besides, this serves to improve adhesion of your tile to the substrate up to 95%.

Note that when spreading the thinset and then when laying your tile on the wall, you may see the mortar penetrating through the mesh of the tile and covering its surface and grout joints. You shouldn’t worry about this, since you can remove the excess residues later – you only need to remove them before the mortar starts hardening. However, when installing face-mounted or plastic face-mount tile, you need to wait until the thinset dries and the paper can be removed, and only after this you will be able to scratch the excesses out.

- After installing several tiles, remove one of them to make sure that you put enough mortar to cover 95% of surface between the tile and substrate – this will help you to correct the thickness of thinset layers for the sufficient coverage.

Tile Leveling

Straighten the sheet of your tile and press it against the prepared surface. Then take a rubber float and a hammer to carefully "beat in" – by tapping easily across the joint between neighboring sheets, you can improve the adhesion and level your glass mosaic, while removing air bubbles between the tile and mortar.

Grout Joints Aligning

- Put each next sheet of your mosaic so that it goes level with the previous one and forms even grout joints, which are equal in the width to the joints between the tile rows on the sheet. If you fail to keep an equal width, you won’t be able to create a smooth, uniform surface – instead, you will get a surface covered with visually separated tile sheets.

- Each 15-20 minutes, take a break from laying your tiles and check if the grout joints are aligned in the section you have already installed. If not, make sure to correct them prior to thinset hardening, without delaying the straightening until the very end of your installation process.

Preparing Grout

- Wait 24-48 hours until the thinset dries and you can start grouting (the exact time depends on environmental conditions and relative humidity).

- Clean the tile surface of mortar and paper using warm water and a sponge and/or nylon brush.

- Clean the grout joints of the excess thinset using a screw driver or a grout scraper. Make sure to scrape out joints of a sufficient depth for proper grouting.

Applying Grout

Grouting has to comply with ANSI A108.10 requirements. Note that some glass tile manufacturers claim that only sandless grout should be used in order to prevent scratches on the tile surface. However, quality glass tile is tolerant to sanded grout, especially when used without excessive force.

- Take a rubber grout float and rub the grout into the joints while holding the float at a 45° angle and moving it diagonally. Make sure that the joints are completely filled with the grout.

- Remove excess grout from the mosaic surface with the help of the float edge, holding it at a 90° angle.

- Wait until the grout dries well enough before you start cleaning the surface. You can check this by pressing it – if only a slight mark left, you can cleanup.

- Take a small amount of water and a small porous sponge to wipe the tile surface, removing excessive grout, while smoothing the joints. Don’t use excessive water, as this can lead to grout color change, shrinkage, cracks and pinholes.

Expansion Joints

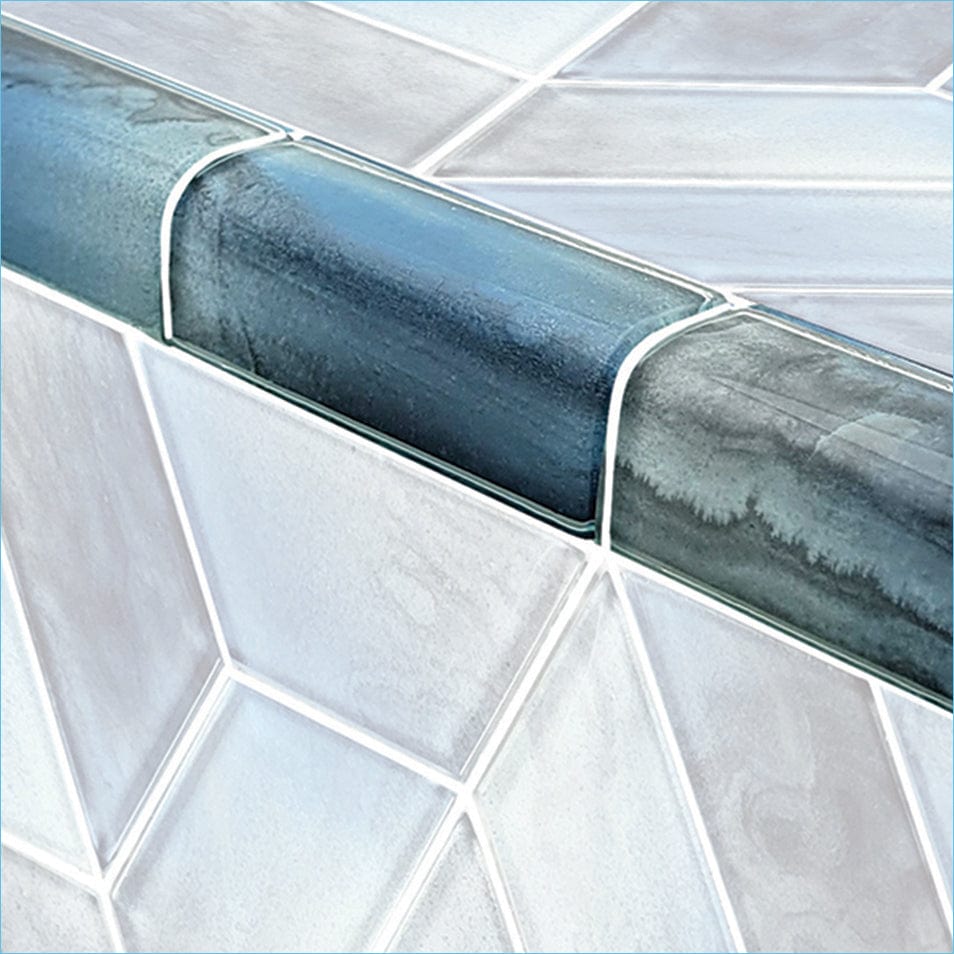

When glass mosaic is installed in pools and other wet areas, it is required to arrange expansion joints within the waterline and at its top, as well as at corners and raised areas where tiles border on other materials. The joints should be located every 8-12 feet and has to comply with TCA method EJ 171.

Since glass tile features a higher expansion/contraction coefficient compared to ceramics, you need to provide some room for the movement within your installation. It is especially true for areas of temperature changes. To address the issue, a flexible sealant should be applied, which is approved for the use in wet areas. Install it between the tiles every 10 feet and in places where the tiles border on restraining surfaces like inside corners, skimmers, water effects, as well as over any joints in the concrete shell. Also, it is very important to use the sealant in areas adjacent to the coping/decking. Though this standard requirement for outdoor installations is often neglected in ceramic tile projects, it is critical to follow the recommendation when it comes to glass tile.